Success Case

Our customer manufactures many products, including transformers. Our customer needs to optimize its control of the parts it receives from its suppliers in order to optimize its manufacturing process.

Our system automates the process of receiving parts from suppliers and then synchronizes the delivery of parts to the appropriate production groups and production lines.

1: Our Client’s Needs

Automate the generation, delivery and receipt of purchase orders

Our system integrates with your ERP to automate the receipt of purchase order and delivery information from our customer's suppliers.

Information accessibility

Consistent and accurate data about the arrival of supplier shipments must be accessible both from our system and your ERP, with no discrepancies.

Allow future scalability

The implemented solution, both software and hardware, must be scalable in order to meet the future needs of the company.

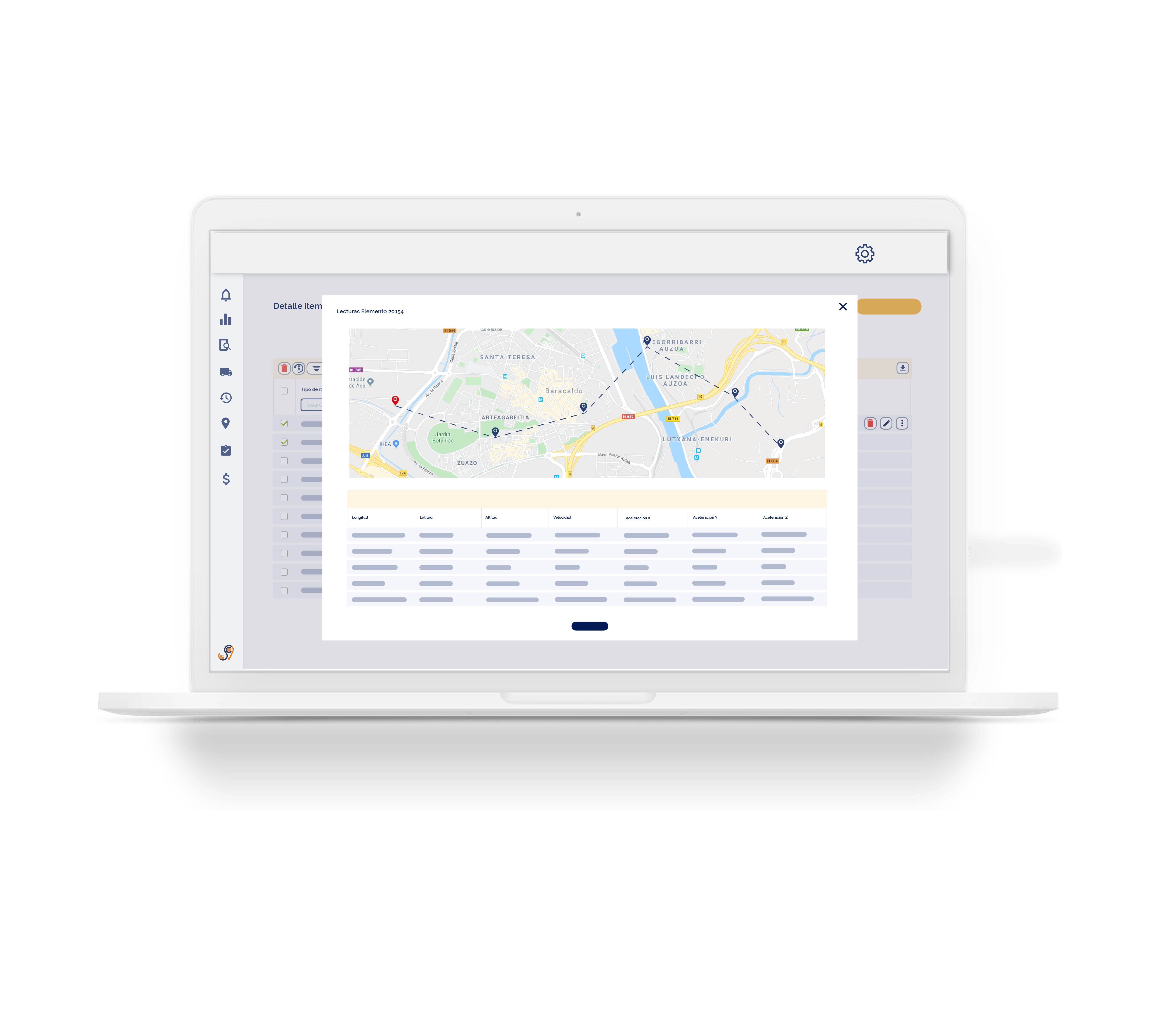

2: Our solution

Integration with the purchase order cycle

The products arrive labeled by the suppliers so that they can be identified automated, so our system integrates with the suppliers' systems to make this happen.

Colocación de hardware de lectura automatizada

Adicionalmente se han colocado portales RFID que posibilitan la lectura automatizada de todo el material que entra y sale por los muelles de carga.

Integration and synchronization with our customer's ERP and other systems

All the information collected by our system is synchronized with our customer's ERP in real time.

The benefits of our solution

Identification of assets

Integration with our customer's systems allows identification of the assets to be controlled.

Improved production processes

Accurate collection and dissemination of data improves the internal production processes by allowing more efficient and effective management of the production processes and the parts involved in those processes..

Increased management control

+14%

Automated receipt of materials from suppliers

Parts are identified automatically as they arrive from suppliers and then immediately transmitted to the customer's ERP.

Future scalability

The software, the system integrations and the hardware infrastructure allows for easy scaling and enhancement in order to automate more processes, establish more control points and drive more efficiencies.

Reduction of waiting times between production groups

-15%

The workflow

Contact Us